Application:

1.Cosmetic and daily chemical product: Cosmetic cream, lotion, shampoo, detergent, health care product, gel, Laundry detergent, hand sanitizer, armpits lotion etc.

2.Pharmaceutical product: Ointment, Ice packs, injection liquid, penicillin etc

3.Food : Salad, mayonnaise, peanut butter, sesame butter, buttery, Animal fat, iced products, healthy food etc.

4. Beverage: Fruit Juice, Milk Juice etc.

5.Chemical: Paints, Pigments, dyes, photo solvents, Rubber and resin, pesticides ,Shoe polish, general chemicals etc.

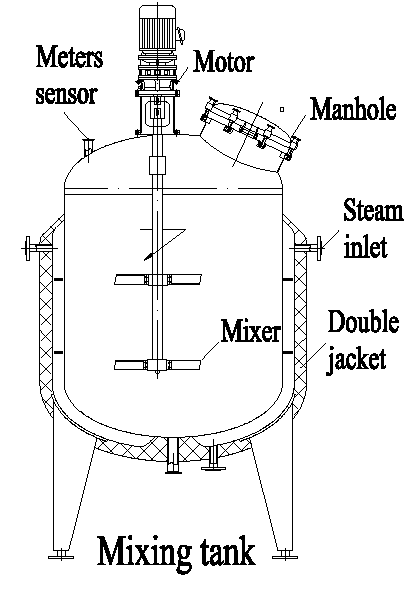

Structure Drawing:

Structure:

This mixing tank include tank, mixer, pipes, meters, valves, temperature control system, heating system, cooling system and control system

The detail requirement should be according to customer’ requirement

Description:

This stainless steel mixing tank is used in the mixing, dispersing, dissolving, emulsification, dissolution, reaction, formulating, heating, cooling, warm-keeping, cultivating, disinfecting and storage etc. Different types of blades and relevant speed achieve the production condition. This mixing tank can be used with combination of flow meter, liquid level indicator, temperature sensor etc. functional accessories. Main shaft seal types: stuffing seal, mechanical seal, and magnetic seal. Jacket can be used to achieve heating preservation, cooling, heating etc.

Parameter:

Feature:

1. Suit for the process about formulating, dissolving, heating, cooling, warm-keeping, cultivating, disinfecting and storage. It is available online CIP cleaning ( only suitable for enclosed structure)

2. Designed in accordance with sanitary requirements, so the structural design is very user-friendly, easy to operate, healthy to store.

3. The inner surface is mirror-polished (roughness Ra≤0.4µm); the welding of all kinds of nozzles, endoscopic, manholes and the pot adopt stretch flanging process arc transition, easy to clean with no dead ends, ensure the reliability and stability in the production process.

4.T he main blending adopts stepless speed variation device, which can reduce the formation of bubbles when the temperature is low and the viscosity is high.

5.The gear pump circulating discharging device can accelerate the forming of products and realize rapid discharging.

Order requirement:

1 How much liter of mixing tank do you need?

2 what this tank used for?

3 What way do you want to heat the mixing tank ? By steam or electric?

4 How much speed of the mixer do you need? Do you need Frequency speed? What is the exactly?

5 When do you need this mixing tank?

6 Do you need automatic control or manual control?

7 Do you need jacket or insulation layer not ?

Prev:PZG Mixing tank

Next:storage tank

MESSAGE